Troubleshooting Vibration Analysis

Field Services

Vibration Analysis Troubleshooting

Vibration analysis is used to help troubleshoot and detect early precursors to machine failure, allowing machinery to be repaired or replaced before the asset fails to perform its function. All rotating equipment vibrates, but as components wear or reach the end of their serviceable life, their vibration signature provides an early warning of the developing problem. Ongoing monitoring of equipment allows technicians to identify these indicators of wear and damage well before a functional failure occurs.

We can employ a multi-faceted approach to vibration analysis in order to more accurately identify your vibration related problems. This can include:

- Single and multi-channel vibration troubleshooting High channel count simultaneous data acquisition

- Remote data collection and analysis for extended periods

- Real-time monitoring and analysis

- Dynamic balancing

Why is vibration analysis important?

- Verification of precision maintenance and increased component life. One of the biggest benefits of vibration analysis is to ensure excessive forces or aggravating conditions are not present which will negatively impact the life of components. Vibration signature analysis from our specialists identifies these faulty conditions before they cause failures that affect your plants reliability.

- Early detection of mechanical fatigue and breakdown. Bearings and components that have some type of defect will produce a unique vibraiton that can be detected and identified before it affects machine operation. Ongoing monitoring of equipment allows these signs of wear and damage to be identified well before an expensive failure occurs.

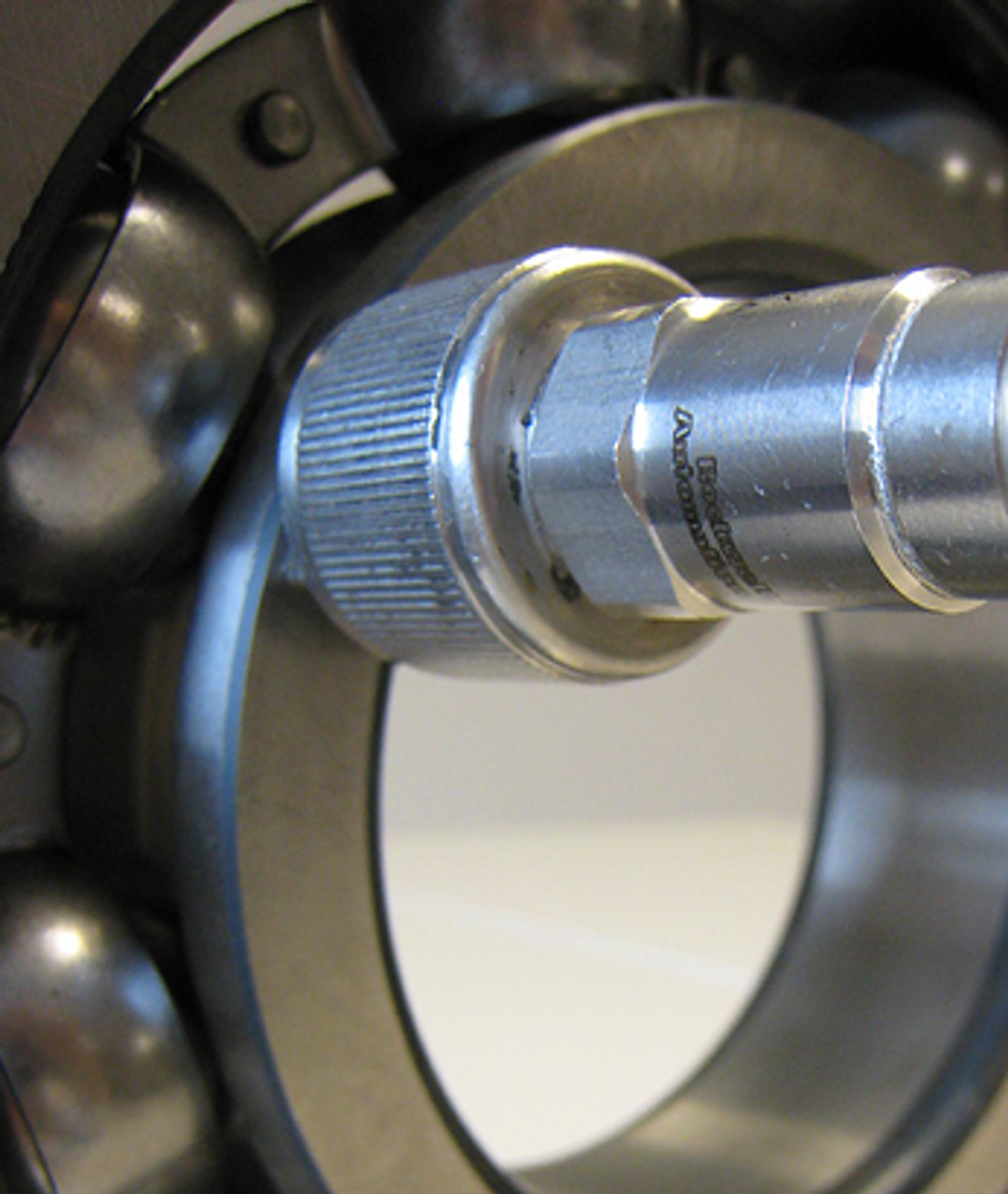

- Accurately monitor the health of your plant machinery. Our vibration analyzers record machine vibrations using transducers such as accelerometers, Insight FDS, proximity probes and tachometers. For each asset, we take vibration measurements at a sufficient number of locations, that we are able to accurately diagnose any problem. The vibration readings are recorded and trended over time. By observing the change in a a machine's vibration signature over time, we can detect any problems at an early stage.

Our capable staff of engineers are trained to utilize a range of tools to quickly identify challenges and will work to develop personalized solutions.

To learn more about our vibration analysis services and to set up a no obligation consultation, contact our sales team or call 970-266-9005.